Some Mistakes to Avoid in ERP Implementation!

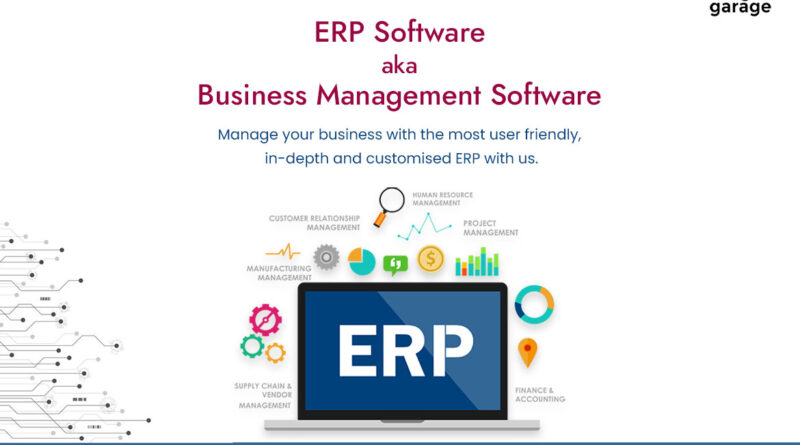

Most manufacturers are concerned about the costs and time involved when they consider implementing an ERP for the first time. Undoubtedly, the ERP implementation life cycle is time-consuming and expensive, but their enhancements make this spend worth it. ERP implementation enhances every aspect of the business, betters every department and makes the business more profitable.

Effective does not come easy, and you and the team need to assess how much disruption are you ready for before starting ERP implementation in your business. Here are 7 common mistakes to avoid when working with an ERP.

Insufficient Planning

Planning is the most crucial step before starting with any ERP solutions. This process will affect every business parameter starting from engineering to operations and everything in between. Thus, a solid step-to-step roadmap will help you tackle such a massive project with ease. In the absence of a well-made plan, there are confusions at every step, which delay and derail the process.

Thus, planning every step beforehand is vital for a successful ERP implementation.

No Leader

Every good team needs a leader. Do not hurry for an ERP implementation before getting a competent leader who will be the holy grail internally for the entire process. The leader should not simply be an employer but the one with great communication skills and influence over the other employees. The leader will not only monitor the ERP implementation process but will be the first contact for every department whenever any complication arises.

No Assessments

Before finding a solution, assessing the problem is more crucial. Talk with the team, and assess the business aspects where you are acing and the ones that need help. As you recognize the areas where improvements are needed, start looking for ERP solutions that address these shortcomings.

Taking No References

Selecting one from many ERP Software Companies in India without any reference is the biggest mistake a manufacturer can commit. Do not get piqued with a salesperson’s pitch that promises swift ERP implementation within a few weeks. Such promises are hollow and come with inadequate systems that lack functionalities and capabilities. The right ERP software need months for proper implementation and running smoothly.

Find the right vendor with proper references. The right vendors can give you at least three references of competitors from your sector who have used their services. Connect with these references and find the advantages, features, and challenges of working with this vendor. A customer who has deployed the services is a better way of assessing a company’s worth than the salesperson working for the provider.

Underestimating the Resources and Time Needed

A majority of manufacturers wrongly estimate the time and resources needed for an ERP system implementation. The right way to gauge the pragmatic amount of time and resources can be calculated by dividing the cost of the software by 100. Moreover, if you take minimum help from experts providing ERP solutions, this calculated time will be doubled.

Not Placing the Key People from Beginning

All the prime players from every department of your organization need to be on board from the beginning of the project. ERP implementation is one of the costliest and most time-consuming processes an organization undertakes, and thus, it is crucial to have all the team members on the same page from the initial stage.

In many organizations, the manufacturers focus on assembling only the executive team overlooking the stakeholders and the prime decision-takers in the initial process. These are the individuals who will put the system in place and not the executive team. So, not involving them from the beginning lags the entire process.

Final Words

While ERP implementation, small mistakes can majorly hamper the process. Thus, assess every step prudently before starting the process.